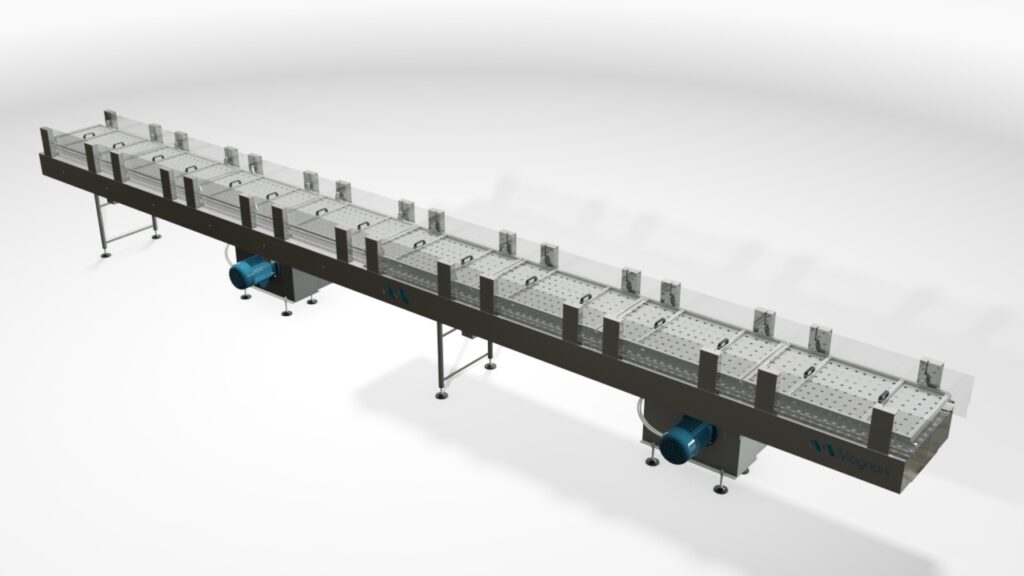

Blowing/drying tunnel

In-line blowing system for full containers, such as tinplate cans and PET/glass bottles. The purpose of this system is to remove water residues by means of high speed air flows.

Pad elevator lowerator

Handling systems for variations in container handling height and suited for bottling lines, the Pad Elevator-Lowerator guarantees great productivity and maximum simplicity of management.

Stagger

The system is ideal to hold the thrust between containers

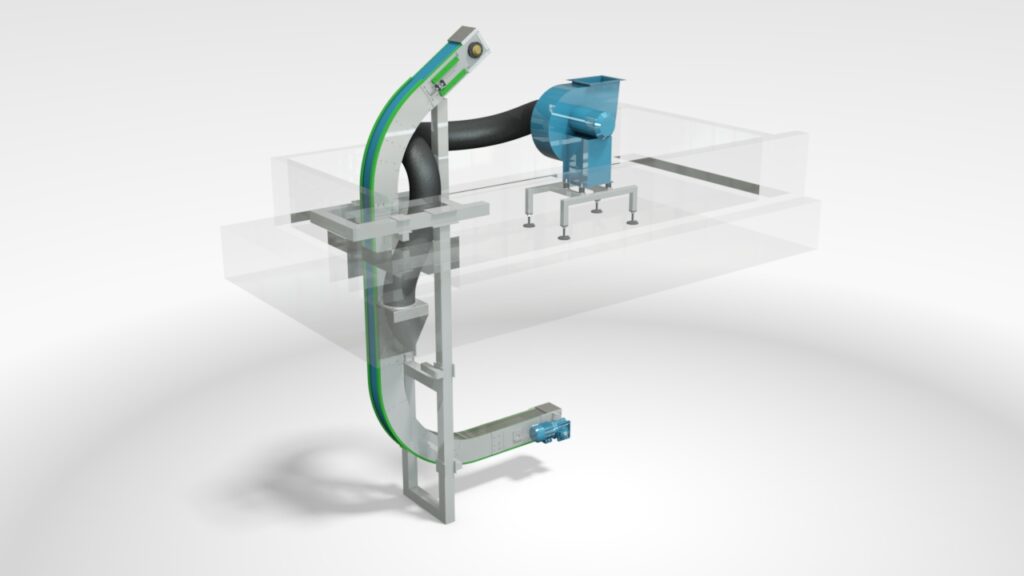

Magnetic Elevator / Lowerator

Conveyor system used to change, by means of belts that run on permanent magnet tracks, the conveyance height of empty or full tinplate containers of varying sizes and weights.

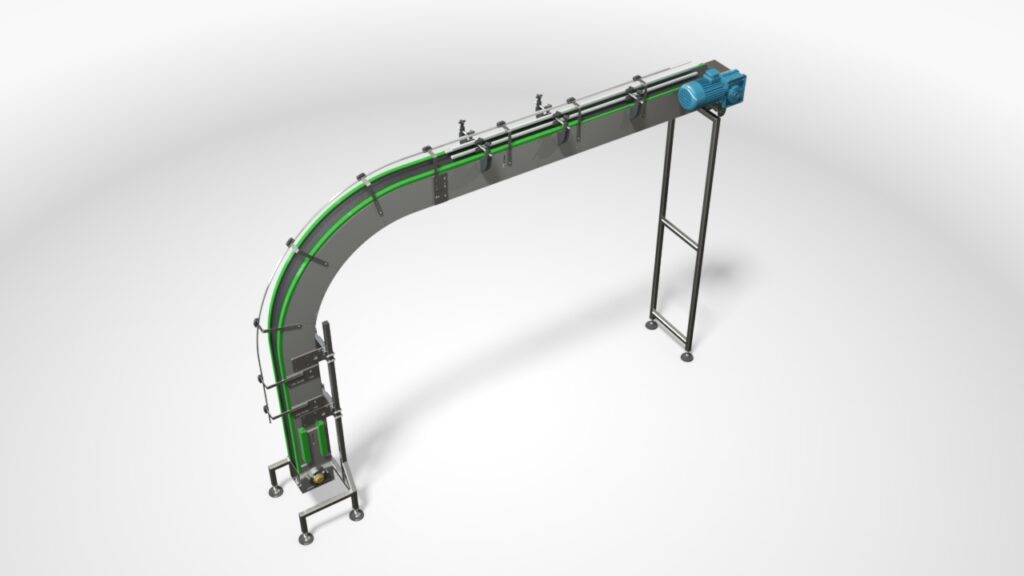

Suction Elevator / Lowerator

Conveyor system used to change at high speed, through suction fans, the transport height of aluminium and plastic containers of small size and low weight.

Suction belt

The suction belt conveyor is used to keep the distance between empty containers during transit on the line, regardless of speed and accelerations and decelerations.

Tipped cans rejecting system

The Tipped cans rejecting system (or Vacuum transfer) is a system that acts on the conveyor belt to reject empty tilted cans, to prevent problems during alignment.

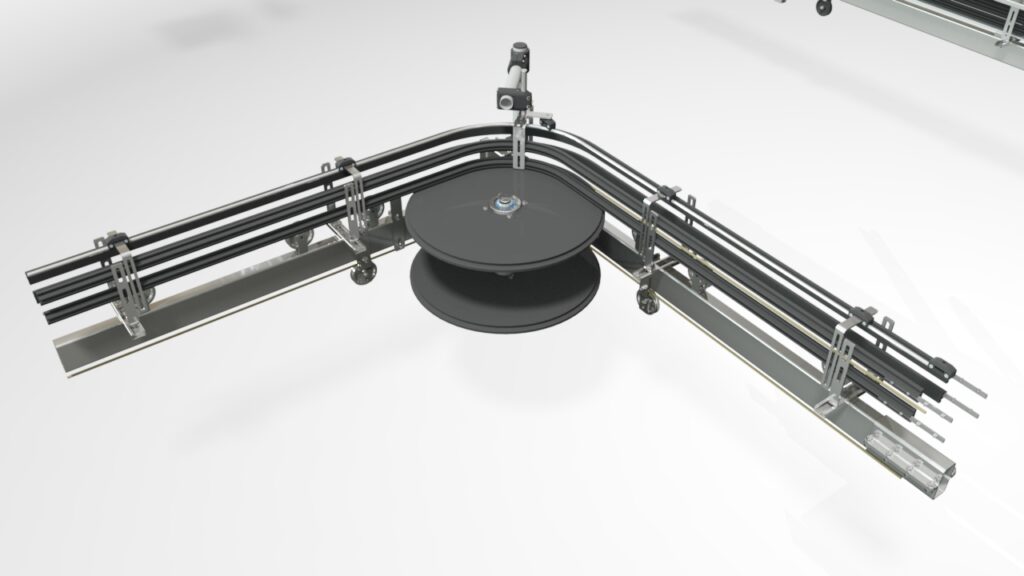

With cable

Conveyor system for moving over long distances and buffering empty cans, or conveying full cans in a single row. Speed up to 90,000 cph.

Mass Air Conveyor

The Mass Air Conveyor is a system for bulk or single-row conveyance and for alignment with one or more rows of cans and jars. It features high speed and low noise level.

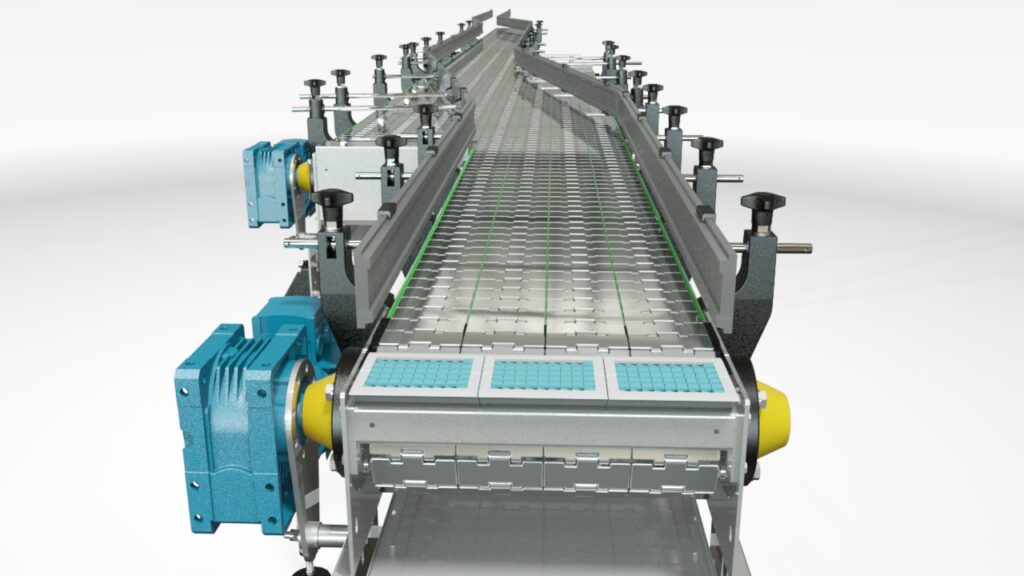

With modular belt and Tabletop chain

Conveyor system for cans, as well as bottles and other primary packaging, this Magnoni Conveyor can be equipped with the modular belt or the slat chain and stands out for its remarkable versatility.