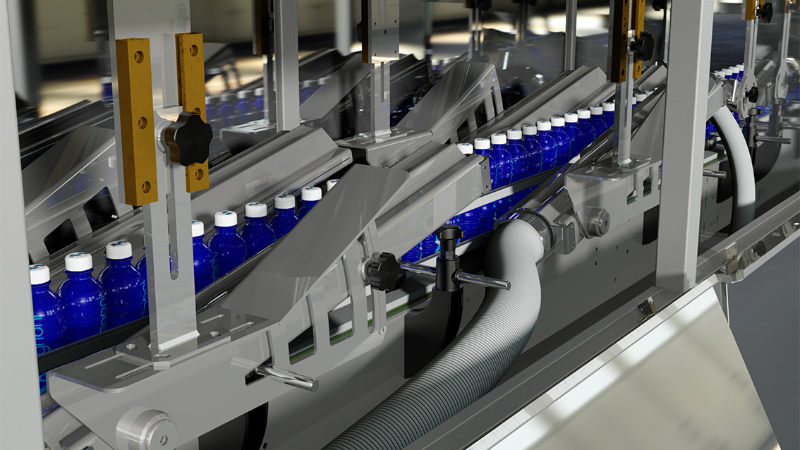

Magnoni’s Blowing Tunnel is located downstream of the filling, pasteurisation or sterilisation operations, which typically leave the surfaces of containers wet; water residues must be removed in order to carry out subsequent labelling, marking and packaging operations and the Blowing Tunnel ensures this through high-speed air flows. The system uses air knife nozzles adjustable in every direction to manage all sizes and shapes of containers and can be combined with a water recovery system. The compact structure is in 304 stainless steel. This product guarantees high level performance with low noise.