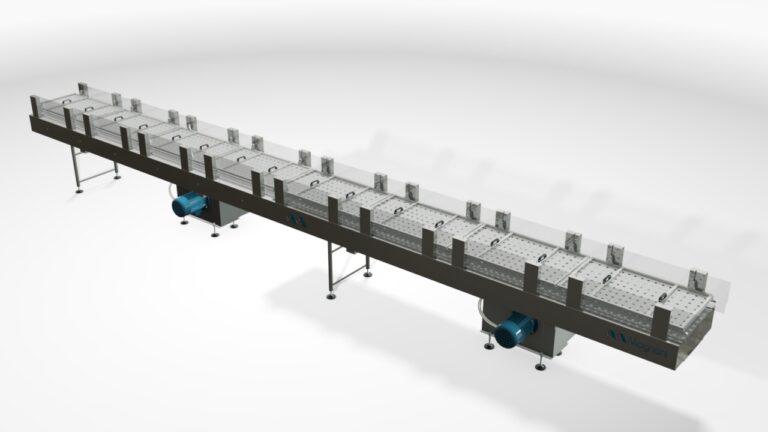

In Magnoni’s wide range, the Mass Air Conveyor is the best solution for bulk or single-row conveyance and for alignment with one or more rows of empty tin cans. The air curtain conveyor is placed downstream of the depalletiser and on infeed to the rinser and filler. Thanks to the low pressure used the air curtain conveyor makes it possible to reduce container damage due to pushing and is functional to feeding high speed rinsers. It stands out owing to high production speed (up to 160,000 cph) and low noise level.

Construction features:

- height of the upper striker plates can be adjusted manually or automatically

- removable clear side guards

- removable upper striker plates

- alignment cone with manual or automatic adjustment

- construction in stainless steel AISI 304

- blowing areas with independently controlled fans

- silenced filters, with easy access for maintenance